ER70S-6(SG2)

BrandStandardsandstreelgradeGaugeWeldingwirechemicalcomposition(%)GBAWSEN14341DINCMnSiPSCrNiMoTiCuYHG3Si1ER50-6ER70S-63Si1SG20.6-5.00.06-0.141.40-1.600.80-1.00<=0.025<=0.025<=0.15<=0.15<=0.15<=0.15<=0

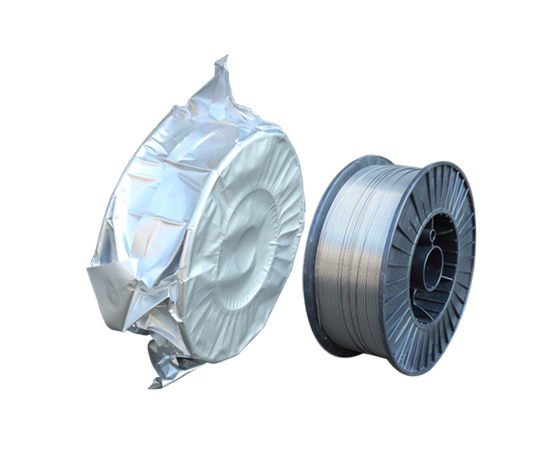

Product Introduction

| Brand | Standards and streel grade | Gauge | Welding wire chemical composition(%) | ||||||||||||

| GB | AWS | EN14341 | DIN | C | Mn | Si | P | S | Cr | Ni | Mo | Ti | Cu | ||

| YHG3Si1 | ER50-6 | ER70S-6 | 3Si1 | SG2 | 0.6-5.0 | 0.06-0.14 | 1.40-1.60 | 0.80-1.00 | <=0.025 | <=0.025 | <=0.15 | <=0.15 | <=0.15 | <=0.15 | <=0.50 |

| Brand | Mechanical properties of deposited metal | APPlication | ||||

| Yield strength (MPa) | Tensile strength (MPa) | Elongation (%) | Akv impact (℃) | Shielded gas | ||

| YHG3Si1 | >=420 | >=500 | >=22 | >=27(-30) | AR+Co2 | Tie in with the fiux intensity for carbon steel and low-level steel such as 16Mn alloy steel manufacturing,such as boilers,pressure vessels of the submerged arc welding. |

Welding wire is a metal consumable used in MIG or TIG welding to create strong, durable joints efficiently.

Keywords:

ER70S-6(SG2)

Product Message

*Attention: Please ensure accurate information filling and maintain smooth communication. We will contact you as soon as possible