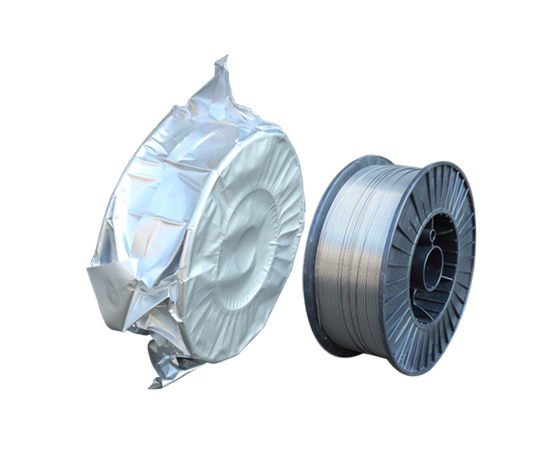

E71T-GS

Category:

Product Introduction

Application: Applicable to the welding of outdoor light structural components and sheets≤1.0mm e.g.small-sized fillet weld,galvanized sheet etc.

Characteristics: This welding wire is 50-kg self-shielded flux-cored welding wire, available for the all-postioning welding.It has a less splash,stable electric arc and beautiful formation of weld during welding.

Chemical Composition Of Welding Wire(Mass Praction)

|

Item |

C |

Mn |

Si |

S |

P |

Ni |

Al |

|

Typical Value |

0.063 |

0.58 |

0.028 |

0.014 |

0.018 |

0.033 |

1.51 |

Mechanical Properties Of Deposited Metal:

|

Item |

Tensile strength ReL/Rp0.2 MPa |

Yield Strength Rm/MPa |

Elongation A% |

Shielding Gas |

Diffusible Hydrogen |

X-Ray |

|

Typical Value |

-- |

568 |

-- |

CO₂ |

10mL/100g |

Ⅱ |

Recommended Welding Parameter:(DC+)

|

Wire Size(mm) |

0.8 |

0.9 |

1.0 |

|

Welding Current(A) |

100-130 |

120-150 |

150-180 |

Note On Usage:

1.It is required to remove the impurities e.g.rust,oilcontaminant,water etc.from the welding workpiece.

2.The extension elongation of welding wire should be controlled between 15-25mm.

3.The interpass temperature should be kept between 135-165℃ in case of the multi-pass welding.

Used for high eficiency welding in all positions with excellent welding performance such as warming electric arc,little spatters,beautiful seam forming and easily moved slag.Suitable for welding of 590 MPA high strength steel,steel structure,bridge,steel pipes,railway vehicle,and construction equipment etc.Keywords:

E71T-GS

Product Message

*Attention: Please ensure accurate information filling and maintain smooth communication. We will contact you as soon as possible