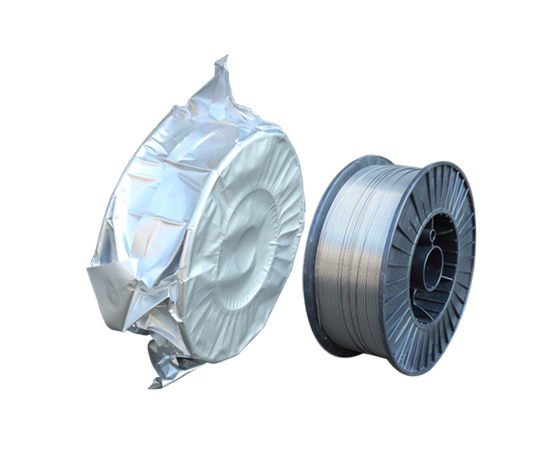

ER5554

Category:

Product Introduction

Application: YH5554 is one kind of aluminium magnesium alloy welding wire off containing magnesium 2.7%,manganese 0.7%and less chromium and titanium.It is able to match with the chemical properties of base materials due to the low magnesium content so as to get excellent corrosion resistance.Its weld metal is not easy to generate the stress corrosion cracking under high temperature with good welding process properties,stable electric arc,beautiful formation of weld and less splash.

Description: Used for the welding of magnesium aluminum alloys with a low corrosion resistance e.g.5454 etc.Such as the welding for relevant magnesium aluminum alloys of relevant industries e.g.transportation,storage tanks,aluminum trailers,automobile hubs, highway trailers,and railway containers etc.

Chemical Composition Of Welding Wire:(Mass Fraction)

|

Item |

C |

Mn |

Si |

Cr |

Ni |

Mo |

P |

s |

Cu |

Ti |

|

Guarantee Value |

≤0.25 |

≤0.40 |

≤0.10 |

0.05 -1.0 |

2.4 -3.0 |

0.05 -0.20 |

≤0.25 |

0.05 -0.20 |

Remain |

≤0.0003 |

|

Typical Value |

0.07 |

0.112 |

0.006 |

0.75 |

2.82 |

0.10 |

0.006 |

0.09 |

Remain |

0.0001 |

Mechanical Properties Of Deposited Metal:(CO₂)

|

Item |

Tensile Strength Rm/MPa |

Yield Strength ReL/Rp0.2MPa |

Elongation A% |

|

Typical Value |

210 |

105 |

20 |

Welding Method:MIG Gas:99.99%Ar

Physical Properties:

|

Melting Temperature(℃) |

Density(g/cm³) |

|

630-645 |

2.65 |

Welding Reference Current:(Current Polarity:MIG DC+TIG AC)

|

MIG |

Wire Size(mm) |

1.2 |

1.6 |

2.0 |

|

Welding Current(A) |

180-300 |

200-400 |

240-450 |

|

|

Welding Voltage(V) |

18-28 |

20-20 |

22-34 |

|

|

TIG |

Wire Size(mm) |

1.6-2.5 |

2.5-4.0 |

4.0-5.0 |

|

Welding Current(A) |

150-250 |

200-320 |

220-400 |

Note On Usage:

1.It is required to remove the oxidation film and oil contaminant from the welding edge workpiece and surface of welding wire.

2.Itis able to support the molten metal with a plate during weldng to ensure the formation of weld.

Used for high eficiency welding in all positions with excellent welding performance such as warming electric arc,little spatters,beautiful seam forming and easily moved slag.Suitable for welding of 590 MPA high strength steel,steel structure,bridge,steel pipes,railway vehicle,and construction equipment etc.

Keywords:

ER5554

Product Message

*Attention: Please ensure accurate information filling and maintain smooth communication. We will contact you as soon as possible