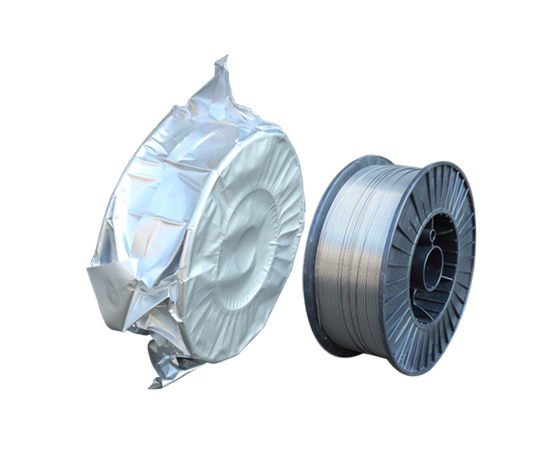

ER316

Category:

Product Introduction

Application: Used for the petrochemical engineering and chemical equipment etc.Such as the welding of materials e.g.06Cr19Ni12Mo2(S316),as well as the welding of high-Cr steel and dissimilar stees with the heat treatment is not required after welding.

Characteristics: This welding wire is 19%Cr-12%Ni-2%Mo type stainless steel welding wire with a good corrosion resistance to acetic acid,sulphurous acid,phosphoric acid and salts due to no Mo.It has a stable welding arc and beautiful formation,available for the all-positioning welding.

Chemical Composition Of Welding Wire:(Mass Fraction)

|

Item |

C |

Mn |

Si |

Cr |

Ni |

Mo |

P |

S |

Cu |

|

Guarantee Value |

≤0.080 |

1.00 -2.50 |

≤0.65 |

18.00 -20.00 |

11.00 -14.00 |

2.00 -3.00 |

≤0.030 |

≤0.030 |

≤0.75 |

|

Typical Value |

0.045 |

1.72 |

0.42 |

19.6 |

12.48 |

2.48 |

0.011 |

0.010 |

0.22 |

Mechanical Property of Deposited Metal

|

Item |

Tensile Strength Rm/MPa |

Elongation A% |

|

Guarantee Value |

≥510 |

≥25 |

|

Typical Value |

580 |

40 |

Note On Usage:

1.MIG welding shield gas flow should be between 18-25L/min;The shield gas should apply Ar+2%O₂;If the wind speed is greater than 0.5m/s,it is required to take the wind-proof measures.

2.TIG welding shield gas flow requirement:If the welding current is between(15-200)A, the gas flow should be(5-14)L/min;If the welding current is between(200-320)A,the gas flow should be(14-24)L/min.The shield gas should apply pure Ar,and please take the wind-proof measures is the wind speed is greater than 1.0m/s;It is required to remove the impurities e.g. rust,oil contaminant,water etc.on welding workpiece prior to MIG/TIG welding;The above- mentioned welding parameters should be for reference only,users should develop the welding standards appropriate for the production according to their own specific conditions.

Used for high eficiency welding in all positions with excellent welding performance such as warming electric arc,little spatters,beautiful seam forming and easily moved slag.Suitable for welding of 590 MPA high strength steel,steel structure,bridge,steel pipes,railway vehicle,and construction equipment etc.

Keywords:

ER316

Product Message

*Attention: Please ensure accurate information filling and maintain smooth communication. We will contact you as soon as possible