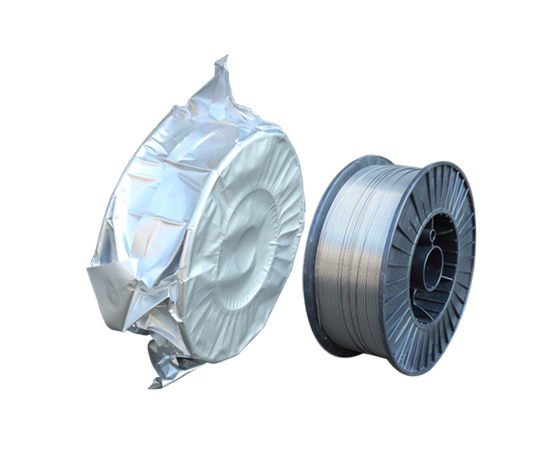

EH14(S4)

Category:

Product Introduction

Application: Used for the union melt welding of carbon steels,low alloy steels with corresponding strength grade e.g.ships,petrochemical engineering,boilers etc.

Characteristics: YH10Mn2 is copper-plated,high-manganese submerged arc welding wire and used with welding flux SJ101 with a good welding process property,beautiful formation of weld and easy deslagging,and a good low-temperature impact toughness.

Chemical Compostion Of Welding Wires:(Mass Fraction)

|

Item |

C |

Mn |

Si |

S |

P |

Cr |

Ni |

Cu |

|

Guarantee Value |

≤0.12 |

1.50-1.90 |

≤0.07 |

≤0.030 |

≤0.030 |

≤0.20 |

≤0.30 |

≤0.35 |

|

Typical Value |

0.08 |

1.65 |

0.04 |

0.014 |

0.013 |

0.034 |

0.02 |

0.19 |

Mechanical Property of Deposited Metal

|

Item |

Tensile Strength Rm/MPa |

Yield Strength ReL/Rp0.2 MPa |

Elongation |

Compound V-Type Notch |

Flux |

|

Guarantee Value |

490-670 |

≥390 |

≥18 |

≥27 |

SJ101 |

|

Typical Value |

525 |

430 |

29 |

83 |

Note On Usage:

1.The welding flux should be used at 250-400℃ for baking 1 to 2 hours.Welding wire should be dry without oil or rust.

2.Please remote the impurities e.g.rust,oil contaminant and water etc.on welding workpiece prior to welding.

Used for high eficiency welding in all positions with excellent welding performance such as warming electric arc,little spatters,beautiful seam forming and easily moved slag.Suitable for welding of 590 MPA high strength steel,steel structure,bridge,steel pipes,railway vehicle,and construction equipment etc.

Keywords:

EH14(S4)

Product Message

*Attention: Please ensure accurate information filling and maintain smooth communication. We will contact you as soon as possible